other products

in the range

The MV valve range (MV200 to MV600) and Precidose 1K ensure constant volumetric dispensing, regardless of fluid viscosity or production conditions.

Compact and robust, the MV models cover a wide range of volumes and flow rates for diverse applications.

Precidose solutions, using progressive cavity pump technology, ensure perfectly controlled flow even at high speeds with the High Flow model.

MV200 / MV250 / MV300

Ensure high-precision dispensing of low to high-viscosity products with outstanding repeatability. Easy and fast quantity calibration.

MV500

Offers precise dispensing of pasty to liquid products with high volumetric flow. Potential dispensing rate: over 600 cycles/minute.

MV600

Designed for dispensing liquids to pasty materials. Offers remarkable accuracy, consistent repeatability, and high flow rate.

Precidose 1K High Flow

With progressive cavity pump technology, this system ensures consistent, accurate dispensing even for ultra-high-viscosity fluids (up to 1,000,000 cps).

Looking for a high-performance dispensing solution ?

achievements

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing s...

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small ...

last articles and news

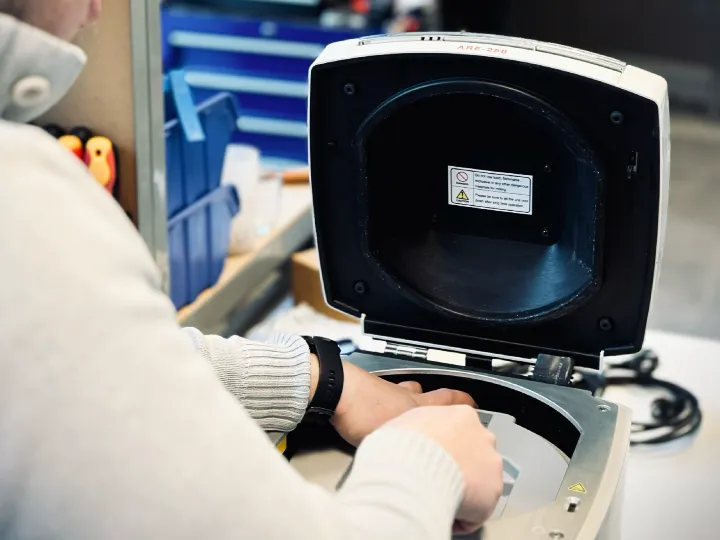

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance