Dispensing Technologies

Our solutions cover both manual dispensing needs and fully automated systems. Regardless of the complexity of your application, we support you in selecting the most suitable technology.

Dispensing Consumables

Poly Dispensing Systems assists you in selecting and qualifying the dispensing consumables required for the precise application of your liquid and paste products. Our complete range includes syringes, pistons, needles, and various accessories all designed to meet the most stringent industrial standards. These consumables are silicone-free, ensuring no contamination of your products.

We offer our consumables in boxed sets, each with a lot number for enhanced traceability. Bulk options are also available to meet larger quantity needs. Thanks to our efficient logistics system, we can deliver your consumable orders within 24 to 48 hours.

We are proud to offer our OPTI syringe range, manufactured in France and meeting the highest quality standards. With Poly Dispensing Systems, you benefit from high-quality products and personalized customer service to meet your dispensing needs with precision and reliability.

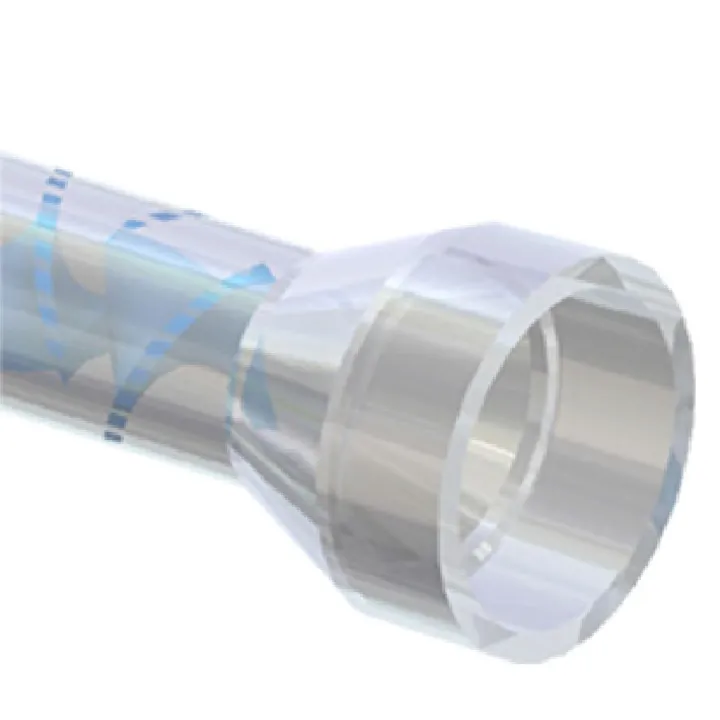

OPTI Range Syringes

OPTI range syringes feature cylindrical barrels with 0° tapering, which minimizes product loss at the syringe tip when the piston reaches the end of its stroke. This design helps optimize production costs by reducing material waste. These syringes are the only ones exclusively compatible with our Precifluid volumetric dispensers and work with two types of OPTI pistons.

OPTI Red Pistons

Red OPTI pistons are more suited for volumetric dispensing. They are divided into two subtypes, including models designed for use with the Precifluid volumetric dispenser, featuring a metal insert that enables magnetization of the piston and screw via the DropTube gun’s magnetic ring.

Precision Stainless Steel Needles

Stainless steel precision needles are intended for micro-dispensing applications with various fluids, such as solder pastes, conductive adhesives, greases, UV adhesives, and thermal pastes. They feature a universal color code and high manufacturing tolerance. The conical shape promotes smooth material flow, reducing pressure drop and resulting in higher flow rates and lower working pressure, thus optimizing dispensing efficiency.

Bell Static Mixer

With its bell-shaped outlet, it allows wide and even material deposition—ideal for coating or filling applications.

Dispensers

The dispensing applicators from Poly Dispensing Systems are specifically designed for dispensing and applying liquid to paste-like products, whether single- or two-component. These include cyanoacrylate, anaerobic, epoxy, silicone, polyurethane, acrylic adhesives, as well as grease, oil, ink, paint, varnish, UV-curable materials, and solder paste.

Our range of dispensers supports dot, bead, potting, and spraying applications. Easy to use, these systems ensure fast operation, repeatable dispensing, and no direct contact with substrates.

Equipped with advanced pneumatic and volumetric technologies, our dispensers are built to meet the most demanding industrial requirements. The pneumatic dispenser range is suitable for a wide variety of applications and can be integrated into robotic systems It is covered by a 5-year warranty.

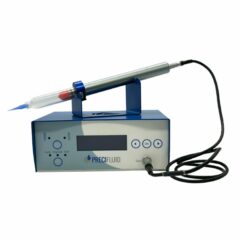

We understand the technical demands of our customers, which is why we offer a complete line of volumetric dispensers using stepper motor technology. The Precifluid® volumetric dispenser can dispense as little as 0.06 µl with 99% repeatability, regardless of the viscosity or viscosity variations of your adhesives. It is equipped with a Swiss-made stepper motor and assembled in France, and can be delivered within 24 to 48 hours.

Compatible with our OPTI syringes (3 cc, 5 cc, 10 cc, and 30 cc), this volumetric dispenser can be integrated into our robots and automated assembly lines for optimal performance and increased flexibility.

Precifluid® Dispenser

The PreciFluid® volumetric dispenser is a technological powerhouse dedicated to your dispensing needs.

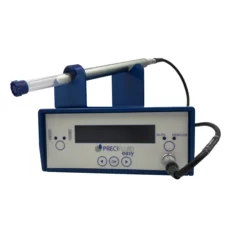

Precifluid® Easy

The Precifluid® Easy is a streamlined version of the Precifluid® Dispenser, compatible with all types of fluids from low- to high-viscosity while maintaining excellent repeatability and precision.

7350

The 7350 time-pressure calibrated dispenser is available in two versions: 0–1 bar, suitable for very liquid products, and 0–7 bar, for all other higher-viscosity materials. It is equipped with a MAC solenoid valve that ensures a stable flow, along with highly accurate dispensing time control adjustable to hundredths of a second.

Dispenser 200 ETC

The 200 ETC (digital) time-pressure dispenser is available in both 0–1 bar and 0–7 bar versions. It is equipped with a MAC solenoid valve that enhances reactivity and durability. This model enables ultra-precise dispensing time settings down to the thousandth of a second and includes an analog timer.

Valves

Poly Dispensing Systems, as a representative of PVA equipment and manufacturer of Precifluid equipment in France and Europe, offers a complete range of dispensing valves for a multitude of applications.

Our valves are compatible with a wide variety of products from the most fluid to the most viscous and use cutting-edge dispensing technologies such as time-pressure, volumetric, piezoelectric jetting, and progressive cavity pump systems.

Whether for precise dot application, regular beads, potting, underfill, dam and fill, glob top, or spraying, our valves are designed to meet your specific needs. They can be integrated into our robots, your automated assembly lines, or manual workstations, ensuring optimal flexibility in your manufacturing process.

Our valves are compatible with a wide range of chemicals, including cyanoacrylate, anaerobic, epoxy, silicone, UV, polyurethane, acrylic adhesives, as well as grease, oil, ink, paint, varnish, and solder paste. We also offer customized valve materials to meet the specific technical requirements of your applications, ensuring optimal performance and a perfect fit with your production environment.

At Poly Dispensing Systems, we are committed to delivering high-quality, precise, and reliable dispensing solutions to effectively meet your fluid dispensing and application needs.

Precidose 1K

High-precision one-component volumetric dispenser. Ensures ±1% repeatability.

Precidose 2K

High-precision two-component volumetric dispenser for mixing and dispensing two-part fluids. Ensures constant, accurate, and 99% repeatable dosing regardless of viscosity changes.

PreciJet®

Non-contact microdispensing of high-viscosity fluids at micro-, nano-, and subnano-liter scales at frequencies over 3000 Hz. Can handle fluids up to 2,000,000 mPas.

Feeding Systems

The feeding systems from Poly Dispensing Systems are designed to ensure clean and reliable supply of adhesives and greases, regardless of the container type cartridges, jars, or drums with capacities ranging from 1 to 200 liters. These systems are suitable for a wide range of products, whether liquid or viscous, and can operate at room temperature or with heat (hotmelt). In addition, they are fully compatible with all valves in the Poly Dispensing Systems range.

Our feeding system range includes various components such as pressure tanks, cartridge holders, drum unloader pumps, diaphragm pumps, and cartridge pumps. These systems can be configured according to the specific needs of your products and manufacturing processes. They offer a variety of flow rates and pressures to meet all production line requirements, with over 99% product extraction from containers, contributing to optimal production capacity.

At Poly Dispensing Systems, we are committed to delivering reliable and efficient feeding solutions to meet the varied dispensing and distribution needs for adhesives, sealants, and greases.

Feeding Systems

Robust solutions for dispensing high-viscosity adhesives and sealants, featuring advanced thermal control and easy maintenance.

Pressure Tanks

Made of high-strength stainless steel, they ensure smooth, accurate delivery of adhesives, oils, and resins, with stirring and vacuum options available.

Two-Component Machines

Our two-component machine range is specifically designed for precise dispensing of a wide variety of two-component materials, whether they have low or high viscosity. This range is perfectly suited to all types of adhesives, regardless of their mix ratio or required dispensing quantity.

In collaboration with GRACO® for over 10 years, our machines ensure the dispensing of dots, beads, and potting using advanced volumetric technology with repeatability higher than 99%. This range includes several models offering exceptional flexibility for diverse applications and products.

Among these models, the PR70 stands out as the most versatile dispensing solution, fully configurable to adapt to all products and applications. Available in fixed or variable ratios, from 1:1 to 24:1, the PR70 is ready to use out of the box, requiring no pre-assembly. PDS offers start-up and training services.

Graco’s fixed-ratio (FFR) and variable-ratio (EVR) electric dispensing systems represent state-of-the-art solutions for two-component adhesives and products. They offer advanced control for high-precision and uniform dispensing applications. These systems are particularly suited for bead dispensing or potting, with mix ratios easily adjustable via an HMI (human-machine interface), covering a wide range from 1:1 to 80:1.

The PR-X two-component system from Graco® is a revolutionary innovation that integrates dispensing, mixing, and distribution technologies driven by servo motors. Designed for applications requiring extremely precise dispensing, even in very small volumes (0.1 cc), the PR-X is compatible with adhesives with mix ratios ranging from 1:1 to 10:1. This versatility makes it an ideal solution for a broad range of industrial applications.

EFR Systems

Motorized 2K dispensing solution offering precise flow control and multi-material compatibility.

Robots

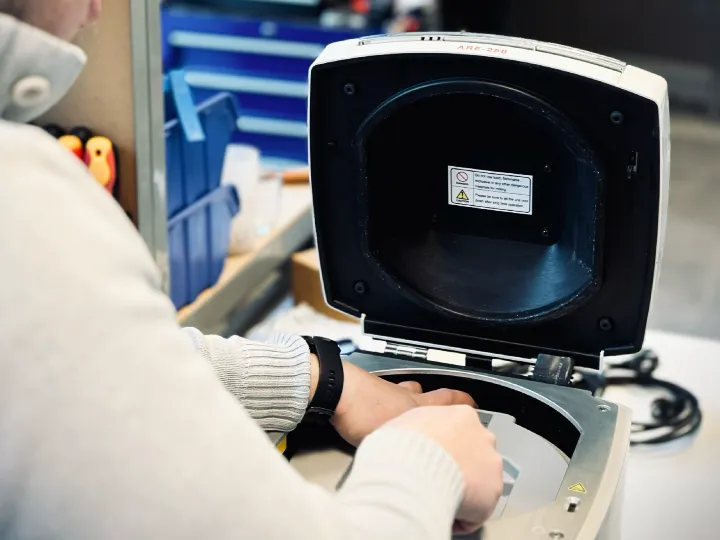

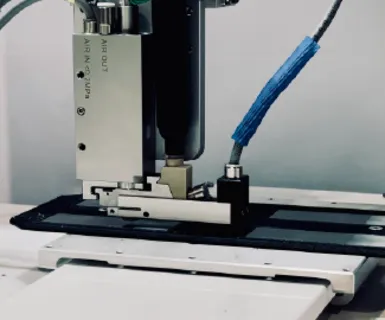

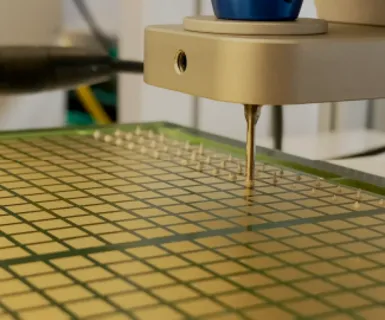

The automated dispensing systems from Poly Dispensing Systems include pre-integrated dispensing functionalities, simplifying programming and ensuring greater placement accuracy and enhanced consistency. These systems are designed for easy installation, allowing for fast and efficient deployment in various production environments.

Dispensing robots offer essential repeatability and precision for assembly operations and automated dispensing systems. Adapted to specific requirements, the dispensing robots from Poly Dispensing Systems are compatible with a wide range of dispensing systems, whether automated or manual. This includes syringes, valves, and UV curing systems. These robots are suitable for a variety of applications, from individual part dispensing to high-volume production.

Available in tabletop and gantry (portal) versions, Poly Dispensing Systems’ robots support various types of deposits including dots, lines, encapsulation, filling, sealing, and jetting. Additionally, a vision system option is available for part recalibration, enabling compliance with the latest industrial requirements and ensuring optimal precision in automated dispensing operations.

Series 781 - Standard 3-Axis

Compact and precise robot, ideal for dot, line, or circular fluid deposits in confined spaces.

Series 782 - Ball Screw 3-Axis

Designed for larger parts, this model offers improved mechanical stability and supports loads of up to 15 kg.

Series 783 - Ball Screw PC 3-Axis

Includes a Windows-based PC with DXF import and CSV export for intuitive programming and accurate cycle monitoring.

Series 784 - Vision 3-Axis

Equipped with a high-resolution camera and laser sensor, it automatically adjusts deposits based on part variations.

Series 785 - Standard 4-Axis

Compact and agile, this robot enables precise dispensing at any angle—even in confined spaces.

Series 786 - Ball Screw 4-Axis

Equipped with ball screws and servo motors, this model offers enhanced stability for complex applications and heavier loads.

Looking for a high-performance dispensing solution ?

achievements

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing system...

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small mecha...

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance