other products

in the range

FC100 and FC300 models are designed for precise and repeatable dispensing of low to medium-viscosity fluids, offering excellent flow control.

The SB300 valve is suited for high-pressure applications involving more viscous fluids, offering enhanced durability and consistency.

For sensitive technical products like cyanoacrylates or anaerobics, the CA753 diaphragm valve ensures reliable dispensing without contamination risk.

Finally, the CA300 valve, compact and cost-effective, provides clean and controlled dispensing of small to medium volumes.

FC100 / FC300

High-pressure dispensing valves suitable for all fluid types. Ideal for applications requiring high-pressure resistance.

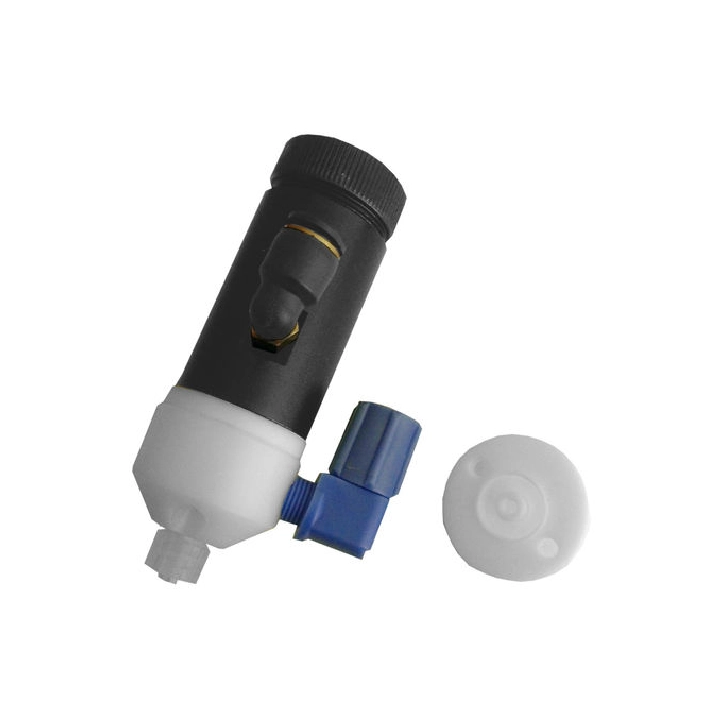

SB300

High-pressure valve for dispensing medium to high-viscosity fluids, including filled products.

CA300

Specially designed for precise deposits of small to medium quantities of fluid products such as cyanoacrylate, anaerobics, lubricants, solvents.

Looking for a high-performance dispensing solution ?

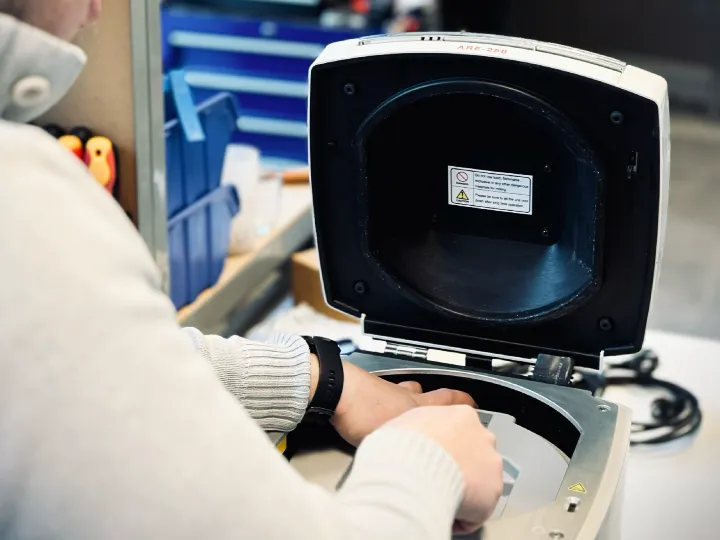

achievements

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing s...

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small ...

last articles and news

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance