Choosing the right type of mixer for your industrial, electronic, aerospace, or automotive needs is a crucial decision that can impact the quality and efficiency of your production. Among the various options available, two types of mixers stand out: the vacuum mixer and the atmospheric mixer.

What is a vacuum mixer?

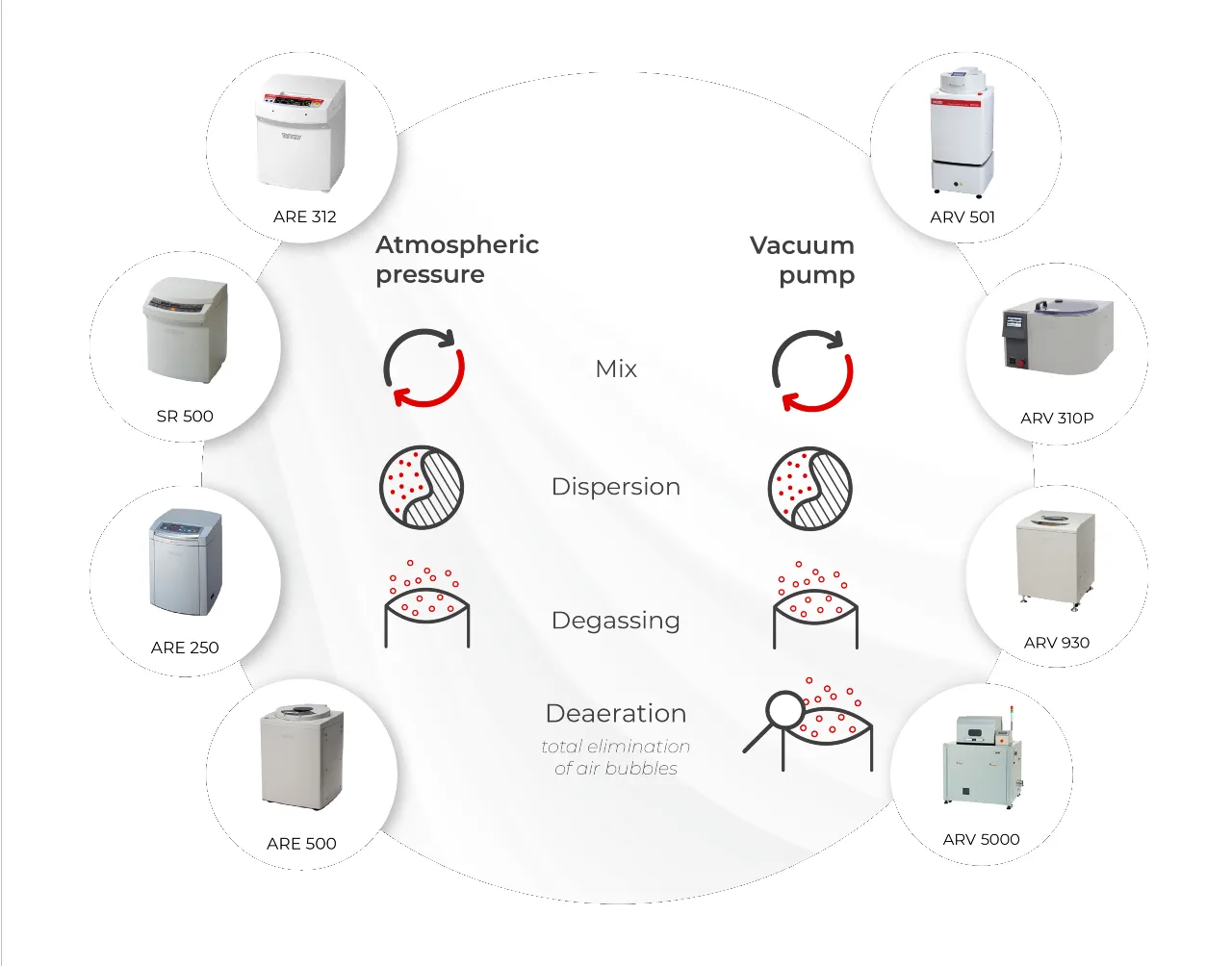

A vacuum mixer such as the THINKY ARV-310P or ARV-5000 is a device that mixes ingredients while removing air from the container. This process occurs under a pressure lower than normal atmospheric pressure, which has several beneficial effects on the final mix.

Advantages of vacuum mixers

- improved product quality: by removing air, the vacuum mixer reduces oxidation, which is particularly beneficial for air-sensitive products.

- uniformity of the mix: thanks to vacuum suction, air bubbles that could cause irregularities are eliminated.

- reduced mixing time: the process is generally faster as vacuum accelerates diffusion.

Applications of vacuum and atmospheric mixers

Mixing specific fluids

- Solder paste fluids: used in electronics for component connections, these fluids require perfect homogeneity to ensure strong joints. a vacuum mixer ensures air is removed, reducing the risk of soldering defects.

- Epoxy and adhesives: vacuum mixers are ideal for epoxy resins as they prevent air bubbles that can compromise adhesion and final product strength. atmospheric mixers, although less expensive, may not provide the same quality level.

- Inks: for printing inks, uniformity and viscosity are essential. using a vacuum mixer produces higher quality ink by minimizing separation and optimizing color and texture.

- Cyanoacrylate mixtures: in some industrial applications, thorough homogenization of cyanoacrylate mixtures is essential to ensure fast and strong curing. vacuum mixers promote this reaction by reducing trapped air in the mix.

What is an atmospheric mixer?

An atmospheric mixer such as the THINKY ARE-500 or ARE-250 operates at ambient pressure and is the most commonly used type of mixer across many industrial sectors.

Advantages of atmospheric mixers

- affordable cost: generally, atmospheric mixers have a lower purchase and maintenance cost.

- ease of use: they are often simpler to operate and maintain, which reduces the need for specialized operator training.

- versatility: these mixers can be used for a wide range of applications, from food products to chemicals and cosmetics.

How to choose between a vacuum mixer and an atmospheric mixer?

Production needs analysis

- product type: if your products are sensitive to oxidation, a vacuum mixer is recommended.

- production volume: for large quantities requiring perfect homogeneity, the vacuum mixer offers significant advantages.

- budget: evaluate the initial cost and operational expenses of each mixer type.

technical considerations

- installation: check available space and installation requirements for each mixer.

- maintenance: consider ease of maintenance and availability of spare parts for each model.

- flexibility: if your production requires frequent recipe changes, an atmospheric mixer may offer greater flexibility.

At Poly Dispensing Systems, we support our clients at every stage to ensure optimal and sustainable use of their systems. This includes setting up automated systems, regular equipment maintenance to prevent breakdowns, and staff training for full mastery of the tools. We also assist clients in selecting materials tailored to their specific needs. Thanks to this comprehensive support, we ensure not only equipment performance but also longevity, while enhancing team skills and optimizing operational processes.

Conclusion

The choice between a vacuum mixer and an atmospheric mixer largely depends on the nature of your products, your production goals, and your budget. Vacuum mixers provide superior quality and increased efficiency but at a higher cost. Conversely, atmospheric mixers are more affordable and versatile but may not suit all product types. By carefully evaluating your needs, you can make an informed decision that will optimize your production process.

Ultimately, investing in the right type of mixer can improve your product quality and production efficiency, resulting in higher customer satisfaction and better profitability. Whatever your choice, ensure you fully understand your specific needs to get the best out of your mixing equipment.