For a perfect, linear, and smooth dispensing directly from your drum.

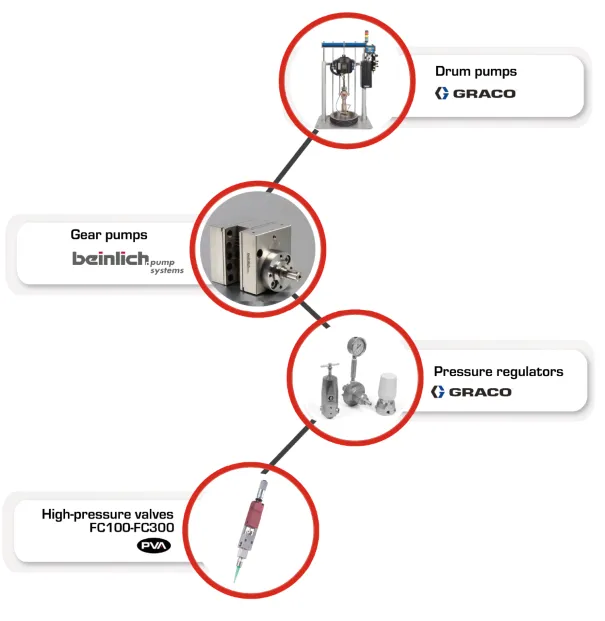

Which equipment should I use to go from my drum to my substrate?

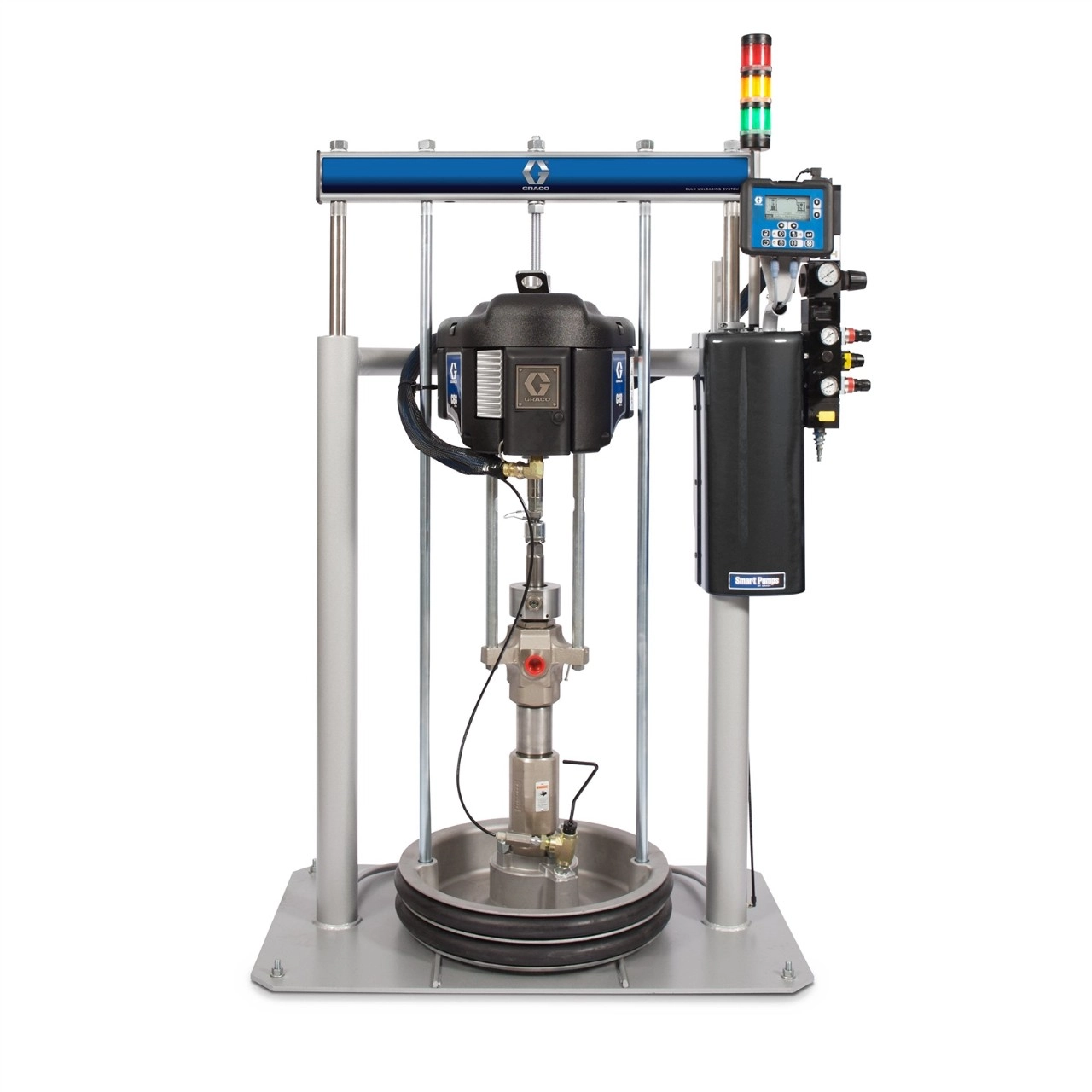

1. Use of drum-emptying pumps

Up to 99% transfer rate for high-viscosity products without dilution or heating. Reduction in manufacturing costs and protection against contamination.

2. Use of gear pumps

- Low pulsation and precise fluid dosing.

- Rapid pressure build-up.

- Extremely precise start & stop dosing.

- Suitable for fluids from low to high viscosity.

- Multiple sealing options available.

3. Use of pressure regulators

- Precise fluid pressure control.

- Suitable for fluids from low to high viscosity.

- Pressure ranges adapted to various applications.

4. Use of high-pressure valves FC100 – FC300

- High pressure resistance.

- Controlled opening and closing.

- Potential cycle rate: over 600 cycles per minute.

- Clean cut-off.