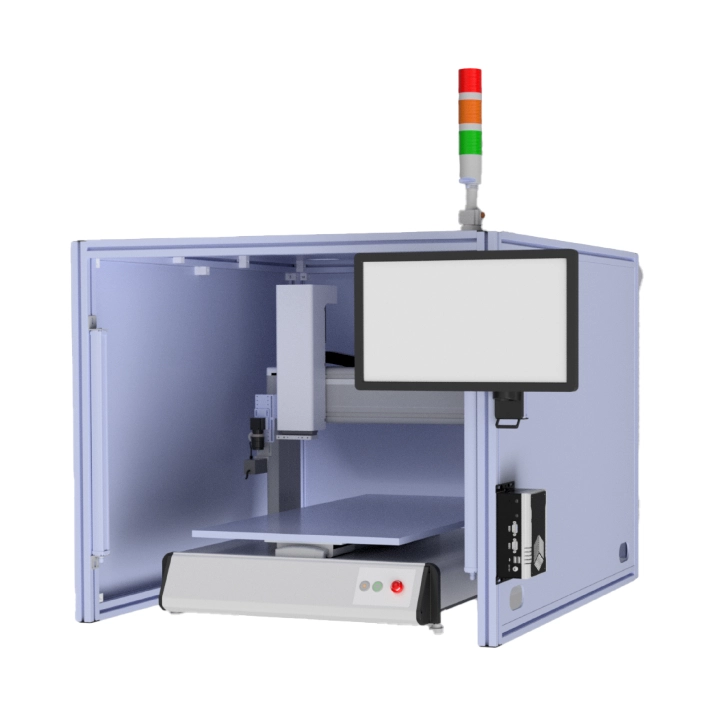

Looking for a high-performance dispensing robots solution ?

achievements

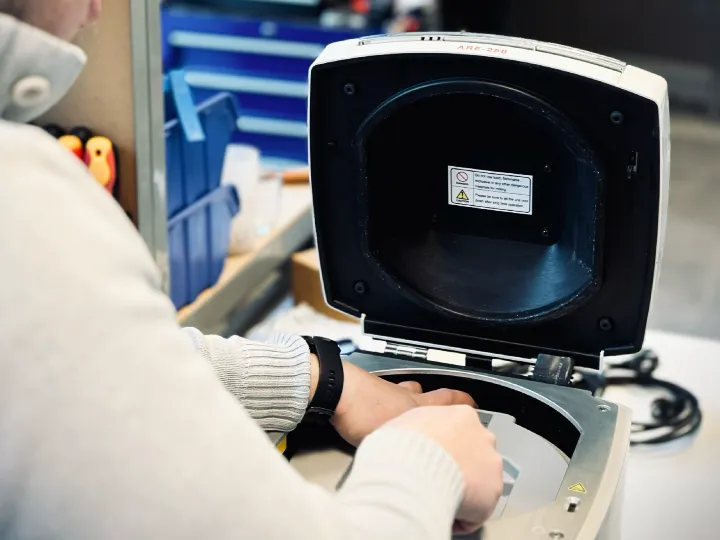

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing s...

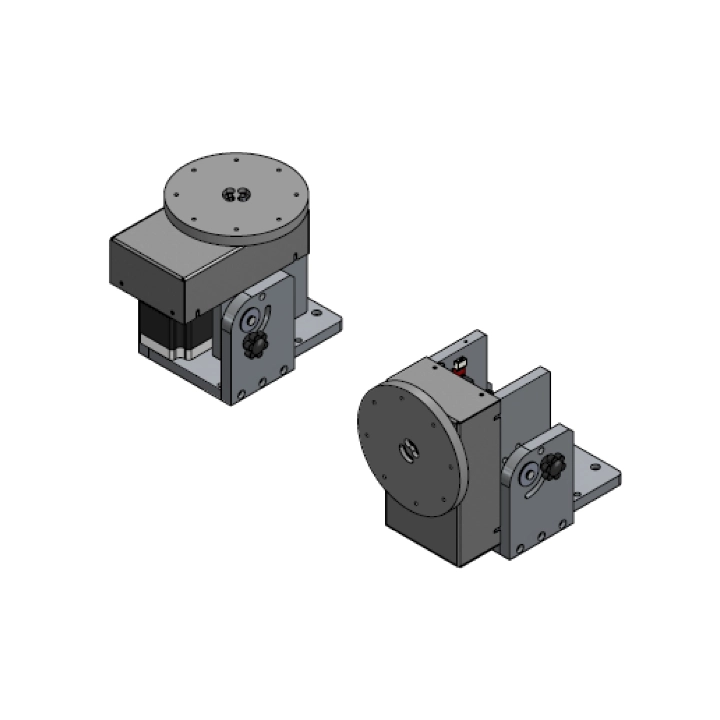

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small ...

last articles and news

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance