other products

in the range

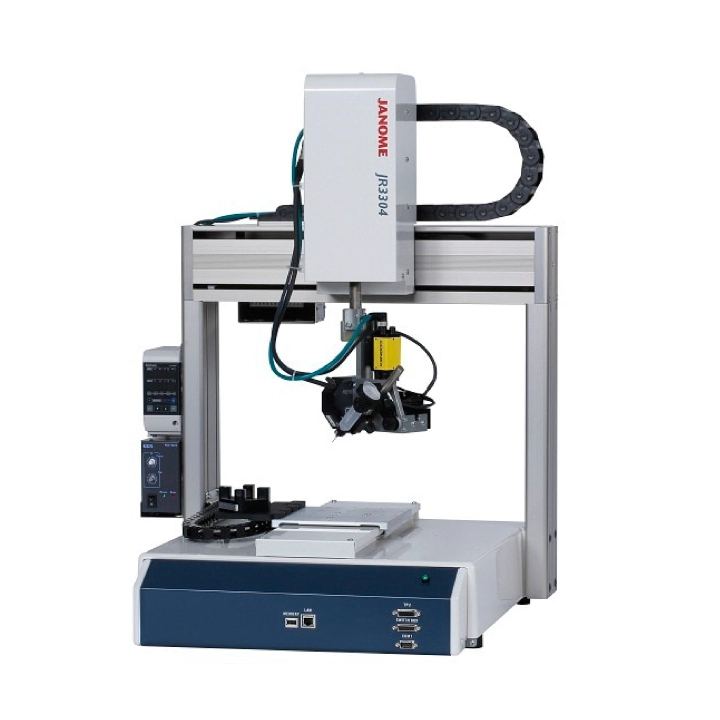

Janome‘s industrial desktop robots are designed to meet the demands of the most challenging automated environments, combining precision, reliability, and efficiency.

The JR3000 series stands out for its ability to optimize repetitive operations with exceptional consistency. It consists of various models tailored to different requirements, including the JR3000 Vision, which features a camera-assisted vision system.

As the natural evolution of the series, the JR4000 takes performance even further—with increased speed, enhanced precision, and greater versatility.

Its robust design and optimized architecture make it a top choice for complex processes and high-throughput production lines.

JR4000

The JR4000 series from Janome marks a significant advancement in desktop robotics, offering notable improvements in speed, precision, and versatility.

Looking for a high-performance dispensing robots solution ?

achievements

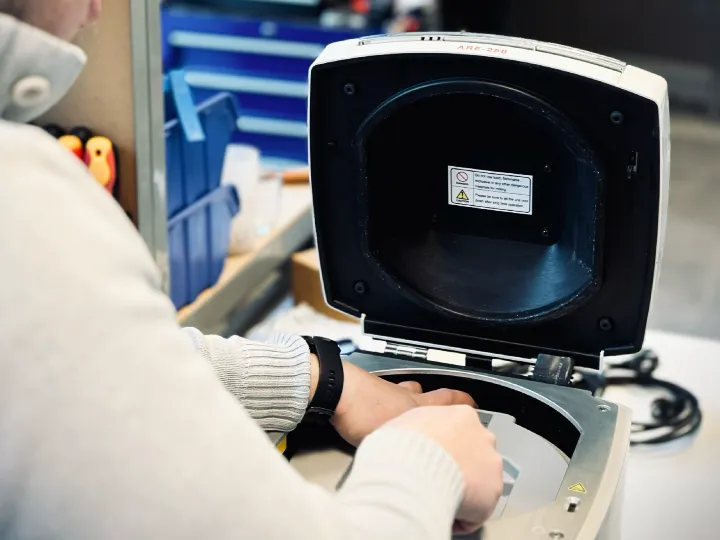

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing s...

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small ...

last articles and news

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance