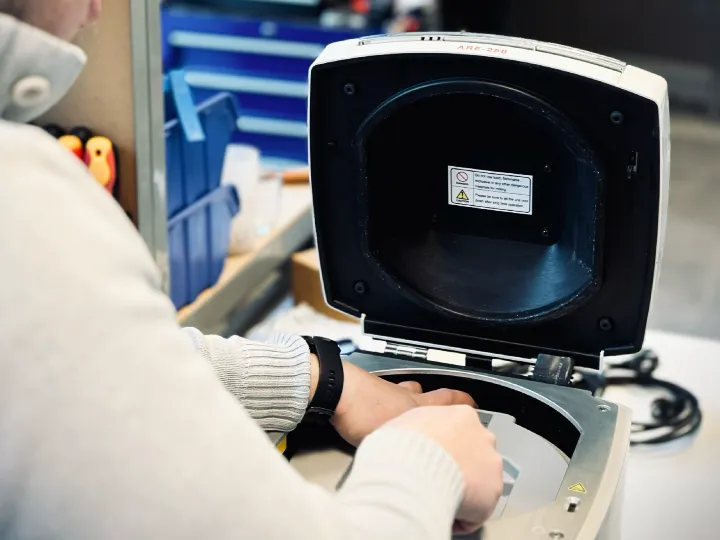

Poly Dispensing Systems offers you a complete range of THINKY planetary mixers, a Japanese pioneer in the field of mixing solutions.

Our range of non-contact mixers offers mixing capacity from a few grams to several kilos, thus allowing great flexibility and adaptability for various applications.

Two types of mixers are available: those operating at atmospheric pressure with a mix and degas mode, and those equipped with a vacuum pump for deeper degassing, eliminating bubbles invisible to the naked eye. Whether for mixing liquid, paste, powder products, or combinations thereof, the result once mixed will homogenize, standardize, and eliminate air bubbles from all your products.

All our mixers are fully adjustable in terms of mixing time and speed to meet the requirements of your most technical applications.

For more than 25 years, THINKY has been revolutionizing the mixing industry and holds an exclusive patent on its degassing principle allowing bubble elimination in a mixture.

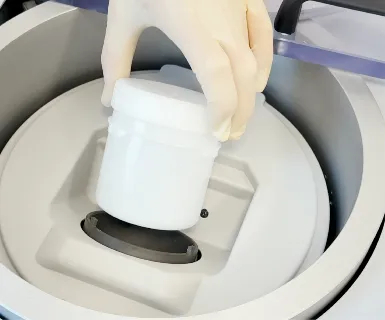

Thanks to a multitude of available containers, you can mix your products in syringes (from 3 to 30ml), in jars (from 12 to 750ml), and up to 4L for your largest volumes.

In addition, accessories are available to personalize your mixing process, such as connected containers for monitoring product temperature, cooling adapters to prevent overheating during mixing, and various other accessories tailored to your needs.

The CE certification attests to the compliance of all our planetary mixers with European safety standards.