Automated Dispensing Systems

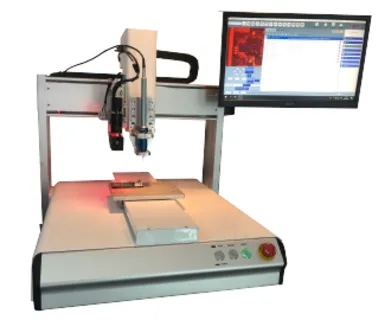

The automated dispensing systems developed by Poly Dispensing Systems are designed to optimize the precise and repeatable application of fluids in industrial production environments. Thanks to their advanced technology, they ensure excellent repeatability while enhancing process quality and efficiency.

Janome Robots

Among the proposed solutions, Janome robots, particularly those from the JR3000 series, stand out for their robust design and compact structure, with optimized cabling for minimal footprint. This series is particularly suited to automating complex tasks thanks to its mechanical stability and fast execution. It also features advanced connectivity, including compatibility with major industrial networks and a LAN port for remote monitoring via PC.

The JR3000 Vision version includes a complete vision system with a camera, laser sensor, and needle adjuster. These tools allow for real-time automatic adjustments, ensuring constant precision even when parts vary in shape or position. The multilingual interface, available in eleven languages, makes programming accessible to a wide range of users. Moreover, the integrated JR C-Points II software centralizes camera calibration, path and sensor management, and enables automatic corrections on the X, Y, and Z axes, as well as nozzle adjustment.

The JR3000 robots are suitable for many industrial applications such as fluid dispensing, coating, potting, greasing, and UV curing. Some models feature a dual table, reducing downtime and increasing production cycles. Their technical performance is solid, with travels ranging from 200 × 200 mm to 400 × 400 mm, maximum speed of 900 mm/s, and ±0.01 mm repeatability. Four-axis versions with 360° rotation are also available for 3D tasks.

JR3000

The JR3000 series from Janome is a line of industrial tabletop robots designed to enhance productivity and precision across various automated processes.

JR4000

The JR4000 series from Janome marks a significant advancement in desktop robotics, offering notable improvements in speed, precision, and versatility.

3-Axis and 4-Axis Robots

For standard 3-axis robots, the 781 series is a standard, versatile solution for fluid dispensing. It enables accurate execution of dots, lines, circles, arcs, and fills, with various working area sizes available. Accuracy reaches 0.001 mm per axis, with a repeatability of ±0.01 mm, and it can store up to 100 programs of 4,000 points each. Control is done via a manual teaching pendant.

The 782 series builds upon this foundation by integrating a ball screw and servo motor, increasing mechanical stability and load capacity up to 12 kg on the Z axis and 15 kg on the Y axis. It also offers advanced communication interfaces, including RS232 and Ethernet. The 783 series integrates a Windows PC, making programming even more intuitive, with the ability to import DXF files to define paths, export data in CSV format, and customize functions (alerts, level sensors, etc.).

The 784 series represents the most advanced version in this range, integrating a high-resolution camera (4 MP) and laser sensor for advanced part recognition. These technologies allow automatic adjustment of the deposit to the part’s geometry and real-time needle height correction. A 19-inch LCD screen is included for easier operation monitoring.

As for 4-axis robots, the 785 series adds a rotary axis enabling deposits at any angle ideal for complex 3D applications. It includes an automatic needle calibration function and is compatible with various syringe or valve systems. The 786 series goes even further in performance by integrating ball screws and servo motors, offering reinforced stability and high precision in rotary movements, with a load capacity up to 15 kg on the Y axis and 5 kg on the Z axis.

Series 781 - Standard 3-Axis

Compact and precise robot, ideal for dot, line, or circular fluid deposits in confined spaces.

Series 782 - Ball Screw 3-Axis

Designed for larger parts, this model offers improved mechanical stability and supports loads of up to 15 kg.

Series 785 - Standard 4-Axis

Compact and agile, this robot enables precise dispensing at any angle—even in confined spaces.

Series 786 - Ball Screw 4-Axis

Equipped with ball screws and servo motors, this model offers enhanced stability for complex applications and heavier loads.

Accessories

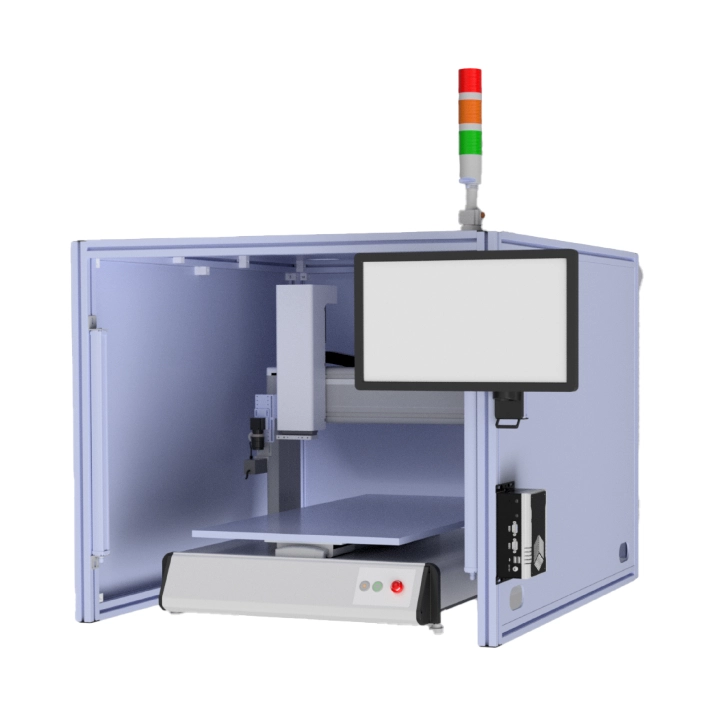

Poly Dispensing Systems also offers a range of options and accessories to enhance its systems. The protective enclosures include a lockable case, optical barrier that instantly stops cycles in case of intrusion, and a door sensor to ensure operator safety.

Automatic recalibration systems allow precise needle alignment: optical sensors detect XY position deviations, and a Z detector adjusts the needle height after each replacement.

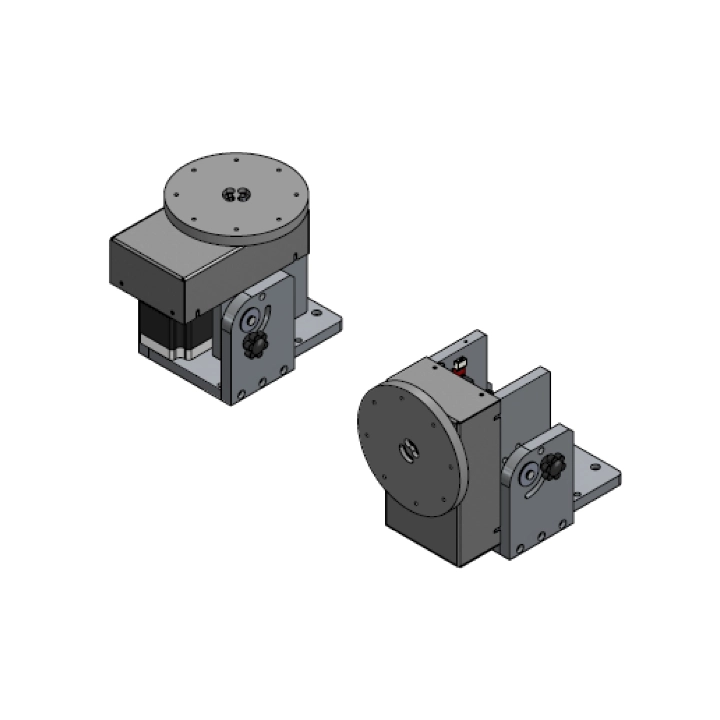

It is also possible to add an auxiliary rotation axis to a 3-axis robot, transforming it into a 4-axis system. This module can be mounted vertically (for multi-face dispensing on a part) or horizontally (to rotate the part itself). This is especially useful for applications on cylindrical components.

Clamps

Protective Safety Enclosures

Automatic Recalibration Systems

Auxiliary Rotation Axis

Summary

In summary, the automated dispensing systems from Poly Dispensing Systems are a comprehensive and high-performance solution. They offer exceptional precision, adaptability to complex processes, and a significant productivity boost thanks to their high level of automation. Reliable, modular, and safe, they effectively meet the needs of manufacturers seeking to optimize quality and production costs.

Looking for a high-performance dispensing robots solution ?

achievements

Jewelry: automation of two-component epoxy adhesive dispensing

Installation of an automated GRACO PR70 dispensing system...

Watchmaking: automation of lubricating oil dispensing

Application of lubricating oil to eccentrics (small mecha...

Technical support

The technical team at Poly Dispensing Systems provides a comprehensive range of services. You can be assured that our experts are trained and specialized in operating all our equipment.

Study

Tailor-made offer

Trials

Delivery installation

Training

After Sales maintenance